PLC programming software is a crucial tool used in the field of industrial automation to create, edit, and debug programs for Programmable Logic Controllers (PLCs). These software packages provide a userfriendly interface to write code, simulate processes, and monitor the behavior of industrial control systems. Here is an overview of PLC programming software and some recommendations for popular options:

Key Features of PLC Programming Software:

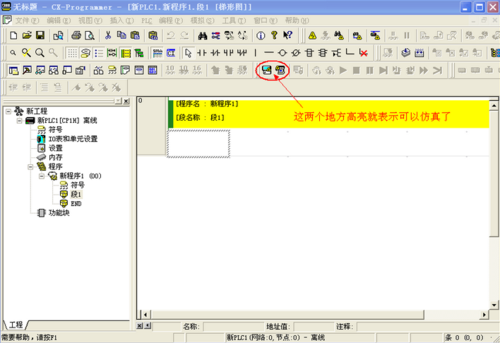

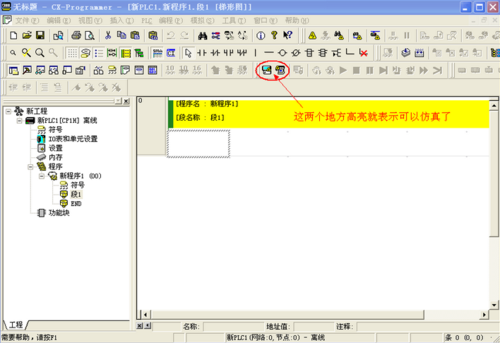

Programming Interface: Most PLC programming software offers a graphical programming interface where users can create ladder logic, function block diagrams, structured text, or other programming languages supported by the PLC.

Simulation Tools: These tools allow programmers to simulate the behavior of the PLC program without connecting to actual hardware, helping in debugging and testing the logic.

Online Monitoring: The software enables realtime monitoring of PLC variables and system status during program execution.

CrossPlatform Compatibility: Some software supports multiple PLC brands, making it easier to work with different systems using the same interface.

Documentation and Diagnostics: Many programs offer features for documentation generation, code commenting, and diagnostics to aid in troubleshooting. Popular PLC Programming Software:

Siemens TIA Portal: TIA Portal is a comprehensive software suite for Siemens PLCs, including SIMATIC S71200, S71500, and more. It offers a unified engineering environment for PLC programming, HMI design, and other automation tasks.

AllenBradley Studio 5000: Studio 5000 from Rockwell Automation is widely used for programming AllenBradley ControlLogix and CompactLogix PLCs. It supports multiple programming languages and offers advanced simulation capabilities.

CODESYS: CODESYS is a versatile development environment that supports various PLC brands and programming languages. It is known for its flexibility and extensive library of function blocks.

Twincat (Beckhoff): Twincat is the programming environment for Beckhoff PLCs based on TwinCAT automation technology. It integrates realtime control with PLC programming and motion control in a single platform.

RSLogix (for older AllenBradley PLCs): RSLogix 500 and RSLogix 5000 are legacy software packages used for programming older AllenBradley PLCs like SLC 500 and ControlLogix 5000 series. Recommendations for Using PLC Programming Software:

When working with PLC programming software, consider the following recommendations to enhance your productivity and efficiency:

Training and Familiarity: Invest time in learning the features and capabilities of the software through training courses, online tutorials, and practice projects.

Version Control: Implement version control practices to track changes in your PLC programs, collaborate with team members, and revert to previous versions if needed.

Testing and Simulation: Use the simulation tools extensively to test your logic and verify the program's behavior before deploying it on actual hardware.

Documentation: Maintain wellorganized documentation within the software to improve readability, troubleshoot issues, and transfer knowledge to other programmers.

Stay Updated: Keep track of software updates and new features released by the vendors to benefit from performance improvements, bug fixes, and additional functionalities.By following these recommendations and utilizing the capabilities of PLC programming software effectively, you can streamline the development process and ensure the reliability of industrial control systems.