Title: Introduction to Programming for Circular Guide Rails

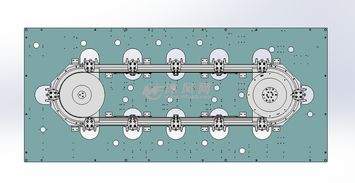

Programming for circular guide rails involves creating instructions for machines equipped with circular tracks or rails, commonly used in various industries such as manufacturing, transportation, and robotics. These rails enable precise movement along curved paths, offering flexibility and efficiency in automated systems. Below, we'll delve into the basics of programming for circular guide rails, covering essential concepts and offering guidance for effective implementation.

Circular guide rails consist of curved tracks or paths along which machinery or devices move. They are utilized in applications where linear motion is insufficient or impractical. These guide rails enable smooth movement around curves, allowing machines to navigate complex paths with precision.

1.

Geometry

: Understanding the geometry of the circular path is crucial for programming. This includes parameters such as radius, arc length, and angle of curvature.

2.

Kinematics

: Knowledge of the kinematics of circular motion is essential. This involves understanding velocity, acceleration, and jerk along the curved path.

3.

Control Systems

: Implementing control systems that regulate the motion along the circular guide rails is vital. This includes PID (ProportionalIntegralDerivative) control and trajectory planning algorithms.

Several programming languages and tools are commonly used for programming circular guide rails:

1.

PLC Programming

: Programmable Logic Controllers (PLCs) are often used for industrial automation involving circular motion. Languages such as ladder logic and structured text are employed for PLC programming.

2.

Motion Control Software

: Dedicated motion control software packages provide specialized tools for programming circular motion. Examples include MATLAB/Simulink, LabVIEW, and Motion Perfect.

3.

Robot Programming Languages

: For robotic systems utilizing circular guide rails, robot programming languages such as Robotic Operating System (ROS) and Gcode may be employed.

1.

Arc Interpolation

: Utilizing arc interpolation techniques to generate smooth motion along the circular path. This involves calculating intermediate points along the arc to ensure continuous movement.

2.

Feedrate Control

: Implementing feedrate control to regulate the speed of motion along the circular guide rails. This ensures optimal performance and prevents issues such as overshooting.

1.

Calibration

: Accurate calibration of the machinery and guide rails is essential for precise motion control. Regular maintenance and calibration procedures should be followed.

2.

Testing and Simulation

: Prior to deployment, thorough testing and simulation of the programmed motion should be conducted to verify performance and identify any potential issues.

Programming for circular guide rails involves understanding the geometry, kinematics, and control systems associated with curved motion. By leveraging appropriate programming languages, tools, and techniques, precise and efficient motion control can be achieved, facilitating various industrial applications.