onebot编程教程

Title: Mastering CNC Programming with OneCNC

CNC (Computer Numerical Control) programming plays a pivotal role in modern manufacturing processes, facilitating the precise control of machinery to create intricate components. OneCNC is a popular software solution designed to streamline CNC programming tasks, offering a range of features to enhance efficiency and accuracy. Let's delve into the world of CNC programming with OneCNC, exploring its key features, benefits, and best practices.

Understanding OneCNC

OneCNC is a comprehensive CAD/CAM software package tailored specifically for CNC machining. It encompasses both CAD (ComputerAided Design) and CAM (ComputerAided Manufacturing) functionalities, allowing users to design parts and generate toolpaths for machining with ease.

Key Features:

1.

CAD Module

: OneCNC's CAD module enables users to create detailed 2D and 3D designs of components, including precise dimensions, shapes, and features.

2.

CAM Module

: The CAM module of OneCNC translates CAD designs into toolpaths, determining the exact movements of CNC machines to manufacture the part.3.

Toolpath Optimization

: OneCNC offers advanced algorithms for optimizing toolpaths, minimizing machining time, and reducing tool wear.4.

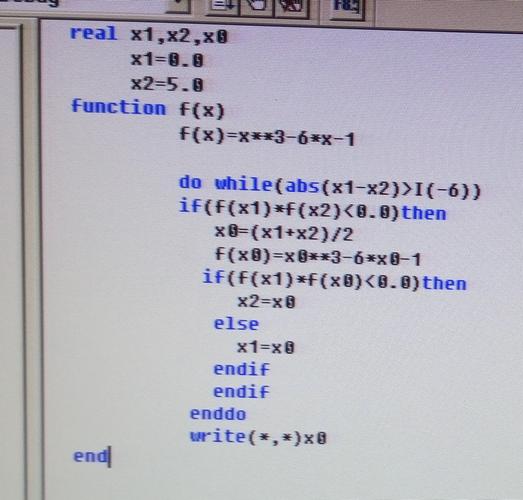

Simulation

: Users can simulate machining processes within OneCNC, allowing them to visualize the entire manufacturing process and identify potential issues before actual production.5.

PostProcessing

: OneCNC supports a wide range of CNC machines and controllers, providing postprocessing capabilities to generate code compatible with specific machine configurations.Benefits of OneCNC Programming

Utilizing OneCNC for CNC programming offers several advantages for manufacturers:

1.

Streamlined Workflow

: OneCNC integrates CAD and CAM functionalities into a single platform, streamlining the designtomanufacture workflow and reducing the need for multiple software tools.2.

Accuracy and Precision

: With OneCNC's advanced simulation capabilities, users can verify toolpaths and ensure the accuracy and precision of manufactured parts, minimizing errors and rework.3.

Time Efficiency

: The optimization algorithms in OneCNC help minimize machining time by generating efficient toolpaths, ultimately improving productivity and reducing lead times.4.

Cost Savings

: By optimizing toolpaths and reducing material waste, OneCNC can contribute to significant cost savings over time, making manufacturing processes more economical.5.

Versatility

: OneCNC supports a wide range of machining operations, from simple drilling and milling to complex multiaxis machining, making it suitable for various industries and applications.Best Practices for OneCNC Programming

To maximize the benefits of OneCNC programming, consider the following best practices:

1.

Master the Basics

: Invest time in learning the fundamentals of CAD design and CAM programming within OneCNC. Familiarize yourself with the software interface, tools, and functionalities.2.

Optimize Toolpaths

: Take advantage of OneCNC's optimization capabilities to minimize machining time and improve surface finish. Experiment with different strategies and parameters to find the optimal settings for your specific application.3.

Utilize Simulation

: Always simulate machining processes within OneCNC before executing them on the actual CNC machine. This helps identify potential collisions, errors, and inefficiencies early in the design phase.4.

Stay Updated

: Keep abreast of software updates and new features released by OneCNC. Updating to the latest version ensures access to improvements, bug fixes, and enhancements that can enhance your programming experience.5.

Training and Support

: Take advantage of training resources, tutorials, and customer support offered by OneCNC. Continuous learning and assistance can help you master the software and overcome any challenges you encounter.Conclusion

OneCNC provides a powerful solution for CNC programming, offering a comprehensive suite of CAD/CAM tools to streamline manufacturing processes and enhance productivity. By leveraging its features and following best practices, manufacturers can optimize efficiency, accuracy, and costeffectiveness in their CNC machining operations, ultimately driving success in today's competitive market.

Whether you're a seasoned CNC programmer or new to the field, mastering OneCNC programming can unlock a world of possibilities in precision manufacturing.